PDF(10158 KB)

PDF(10158 KB)

PDF(10158 KB)

PDF(10158 KB)

PDF(10158 KB)

PDF(10158 KB)

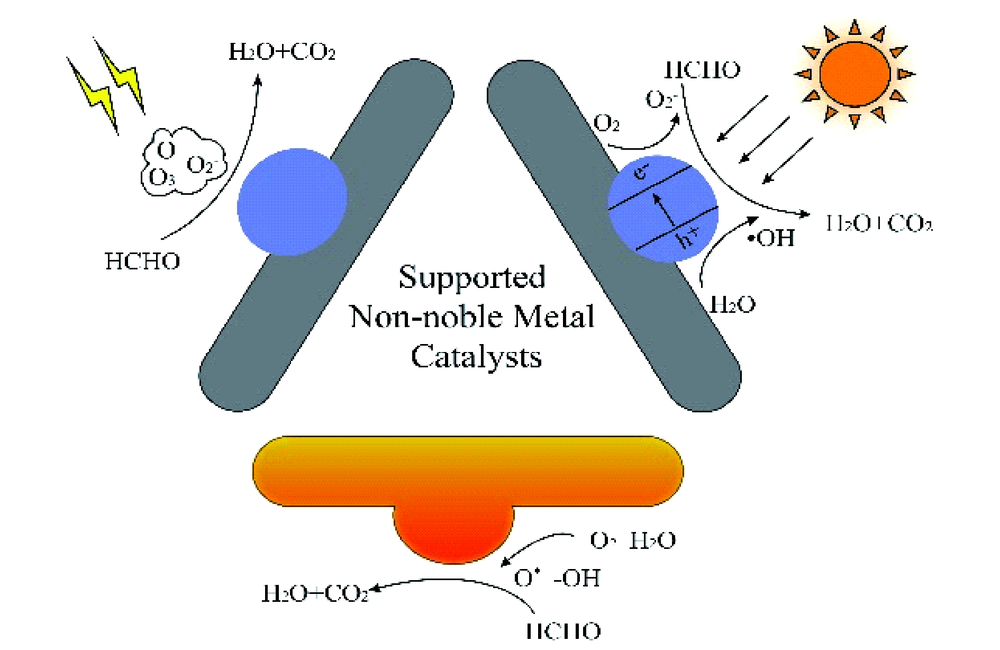

负载型廉价金属催化剂在低温催化氧化甲醛中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Application of Supported Non-Noble Metal Catalysts for Formaldehyde Oxidation at Low Temperature

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |