PDF(15724 KB)

PDF(15724 KB)

PDF(15724 KB)

PDF(15724 KB)

PDF(15724 KB)

PDF(15724 KB)

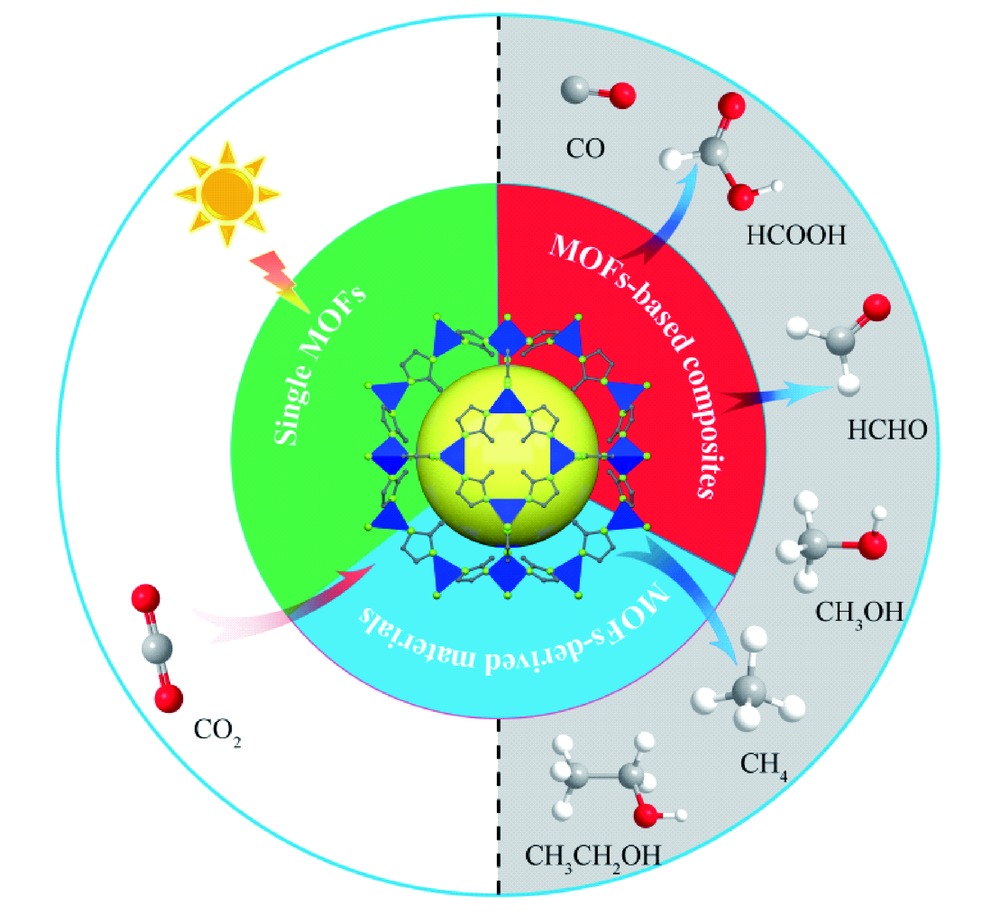

金属-有机框架材料在光催化二氧化碳还原中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Application of Metal-Organic Framework Materials in the Photocatalytic Carbon Dioxide Reduction

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |