PDF(12200 KB)

PDF(12200 KB)

MOFs衍生金属氧化物及其复合材料在锂离子电池负极材料中的应用

陈豪登, 徐建兴, 籍少敏, 姬文晋, 崔立峰, 霍延平

化学进展 ›› 2020, Vol. 32 ›› Issue (2-3) : 298-308.

PDF(12200 KB)

PDF(12200 KB)

PDF(12200 KB)

PDF(12200 KB)

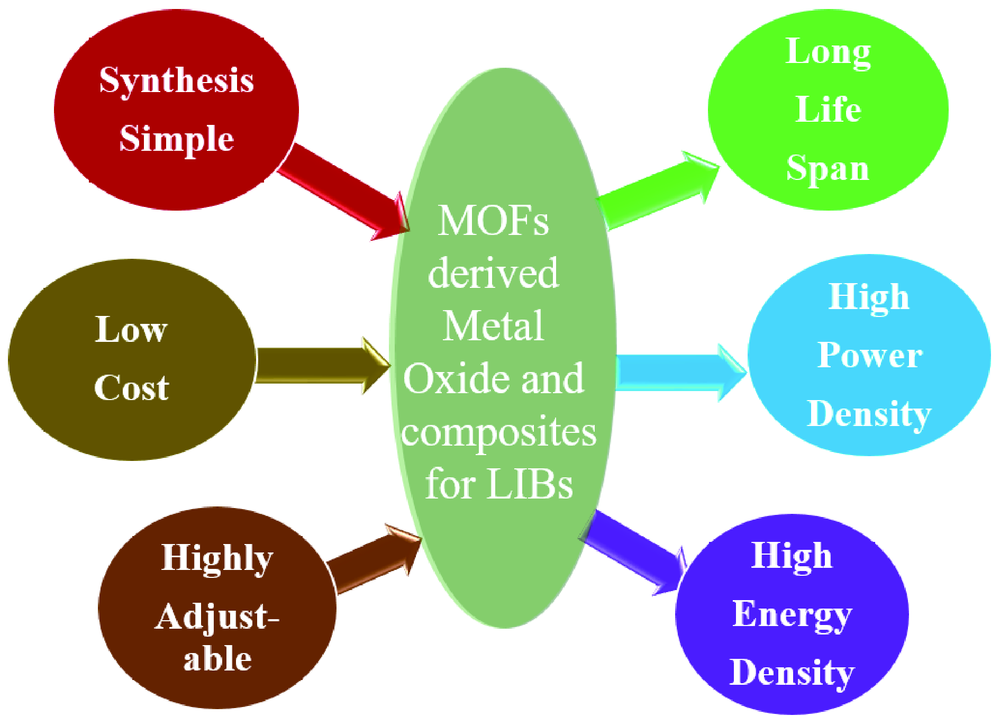

MOFs衍生金属氧化物及其复合材料在锂离子电池负极材料中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Application of MOFs Derived Metal Oxides and Composites in Anode Materials of Lithium Ion Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |