PDF(3089 KB)

PDF(3089 KB)

PDF(3089 KB)

PDF(3089 KB)

PDF(3089 KB)

PDF(3089 KB)

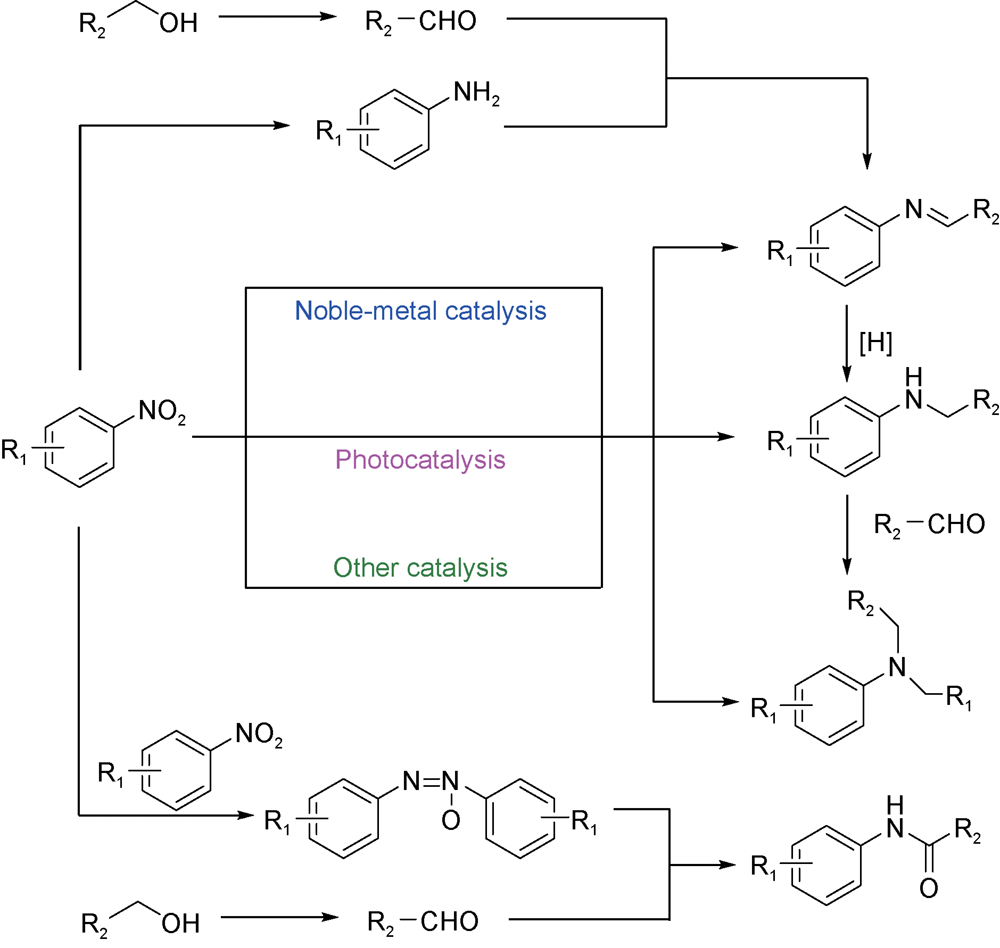

硝基芳烃与醇还原胺化:催化剂和催化机制

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Reductive Amination of Nitroarenes and Alcohols: Catalyst and Catalytic Mechanism

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |