PDF(11326 KB)

PDF(11326 KB)

PDF(11326 KB)

PDF(11326 KB)

PDF(11326 KB)

PDF(11326 KB)

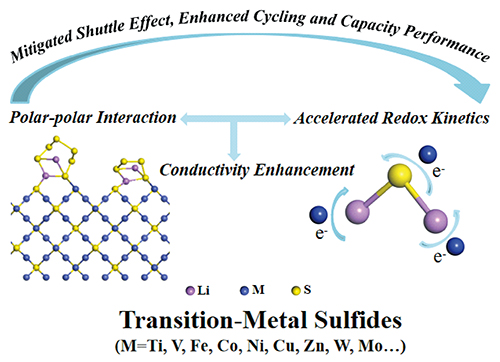

过渡金属硫化物改性锂硫电池正极材料

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Transition-Metal Sulfides Modified Cathode of Li-S Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |