PDF(1496 KB)

PDF(1496 KB)

PDF(1496 KB)

PDF(1496 KB)

PDF(1496 KB)

PDF(1496 KB)

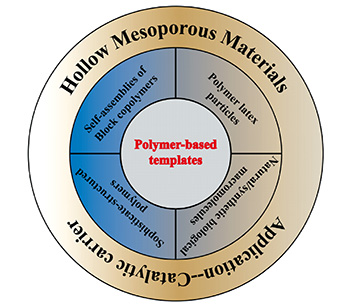

聚合物基模板制备中空介孔材料

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation of Hollow Mesoporous Materials by Polymer-Based Templates

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |