PDF(9894 KB)

PDF(9894 KB)

PDF(9894 KB)

PDF(9894 KB)

PDF(9894 KB)

PDF(9894 KB)

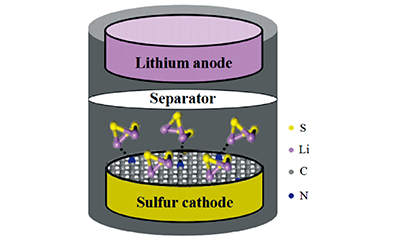

锂硫电池中的石墨烯掺杂

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Doped-Graphene in Lithium-Sulfur Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |