PDF(5137 KB)

PDF(5137 KB)

PDF(5137 KB)

PDF(5137 KB)

PDF(5137 KB)

PDF(5137 KB)

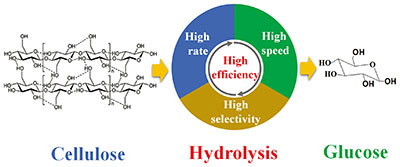

化学法催化纤维素高效水解成糖

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}High Efficient Hydrolysis of Cellulose into Sugar by Chemical Catalytic Method

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |