PDF(14829 KB)

PDF(14829 KB)

PDF(14829 KB)

PDF(14829 KB)

PDF(14829 KB)

PDF(14829 KB)

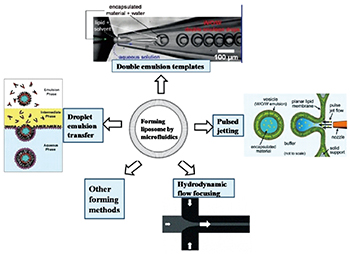

脂质体类药物载体的微流控制备

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Microfluidic Fabrication of Liposomes as Drug Carriers

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |