PDF(6277 KB)

PDF(6277 KB)

PDF(6277 KB)

PDF(6277 KB)

PDF(6277 KB)

PDF(6277 KB)

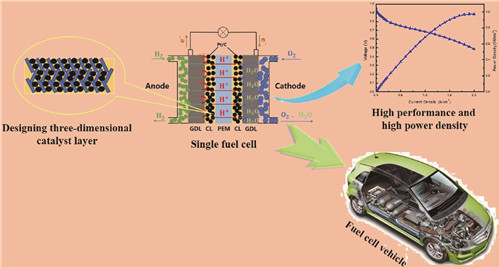

高性能高功率密度质子交换膜燃料电池膜电极

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}High Performance and High Power Density Membrane Electrode Assembly for Proton Exchange Membrane Fuel Cells

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |