PDF(941 KB)

PDF(941 KB)

PDF(941 KB)

PDF(941 KB)

PDF(941 KB)

PDF(941 KB)

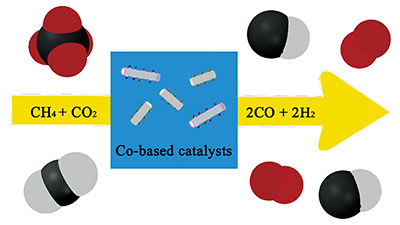

甲烷二氧化碳重整制合成气钴基催化剂

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Co-Based Catalysts for Carbon Dioxide Reforming of Methane to Synthesis Gas

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |