PDF(6831 KB)

PDF(6831 KB)

氧化石墨烯和石墨烯量子点的两亲性调控及其在Pickering乳液聚合中的应用

卫林峰, 马建中, 张文博, 鲍艳

化学进展 ›› 2017, Vol. 29 ›› Issue (6) : 637-648.

PDF(6831 KB)

PDF(6831 KB)

PDF(6831 KB)

PDF(6831 KB)

氧化石墨烯和石墨烯量子点的两亲性调控及其在Pickering乳液聚合中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

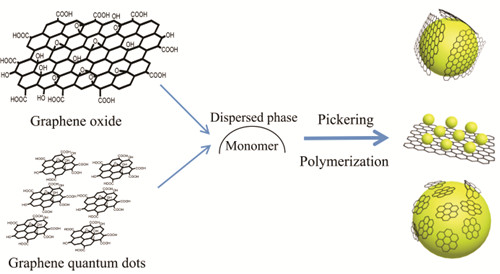

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}The Amphipathy Adjustment of Graphene Oxide and Graphene Quantum Dots and Their Application in Pickering Emulsion Polymerization

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |