PDF(2124 KB)

PDF(2124 KB)

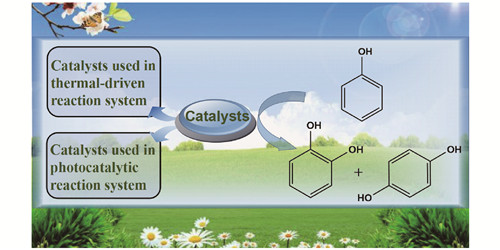

苯酚直接羟基化制备苯二酚反应体系中催化剂的设计与性能

海莉, 张天永*, 李彬*, 姜爽*, 张夏, 马骁媛, 张光辉

化学进展 ›› 2017, Vol. 29 ›› Issue (7) : 785-795.

PDF(2124 KB)

PDF(2124 KB)

PDF(2124 KB)

PDF(2124 KB)

苯酚直接羟基化制备苯二酚反应体系中催化剂的设计与性能

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Design and Performance of Catalysts for Direct Hydroxylation of Phenol to Dihydroxybenzene

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |