PDF(1959 KB)

PDF(1959 KB)

PDF(1959 KB)

PDF(1959 KB)

PDF(1959 KB)

PDF(1959 KB)

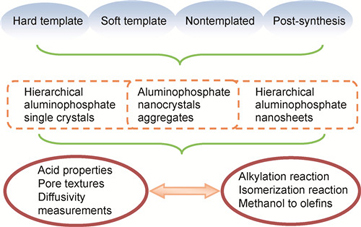

多级孔磷酸铝分子筛的合成、表征及催化应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Synthesis, Characterization and Catalytic Applications of Hierarchically Porous Aluminophosphate Molecular Sieves

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |