PDF(1421 KB)

PDF(1421 KB)

聚乙二醇功能化离子液体的制备及其在有机反应中的应用

徐艺凇, 张凤香, 厉嘉云, 白赢, 肖文军, 彭家建

化学进展 ›› 2015, Vol. 27 ›› Issue (10) : 1400-1412.

PDF(1421 KB)

PDF(1421 KB)

PDF(1421 KB)

PDF(1421 KB)

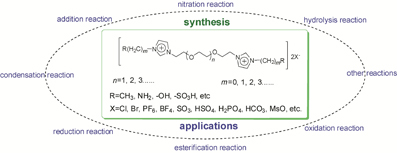

聚乙二醇功能化离子液体的制备及其在有机反应中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation and Applications in Organic Reactions of Polyethylene Glycol Functionalized Ionic Liquids

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |