PDF(1996 KB)

PDF(1996 KB)

PDF(1996 KB)

PDF(1996 KB)

PDF(1996 KB)

PDF(1996 KB)

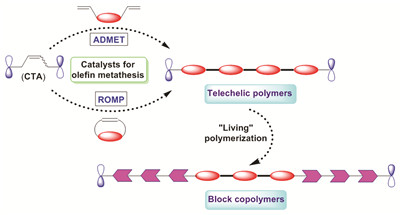

烯烃易位聚合制备遥爪聚合物及嵌段共聚物

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Telechelic Polymers and Block Copolymers Prepared via Olefin-Metathesis Polymerization

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |