PDF(4484 KB)

PDF(4484 KB)

PDF(4484 KB)

PDF(4484 KB)

PDF(4484 KB)

PDF(4484 KB)

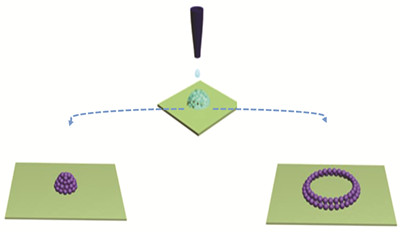

喷墨打印中“咖啡环”效应的调控及应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Control and Application of “Coffee Ring” Effect in Inkjet Printing

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |