PDF(1047 KB)

PDF(1047 KB)

PDF(1047 KB)

PDF(1047 KB)

PDF(1047 KB)

PDF(1047 KB)

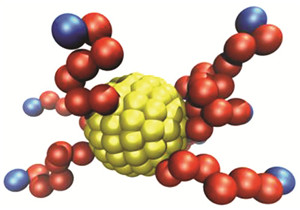

金纳米粒子和聚合物复合体系分子设计与组装过程的计算机模拟

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Computer Simulation Study on the Molecular Design and the Self-Assembly Process of Au-Nanoparticle and Polymer Composite System

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |