PDF(12461 KB)

PDF(12461 KB)

PDF(12461 KB)

PDF(12461 KB)

PDF(12461 KB)

PDF(12461 KB)

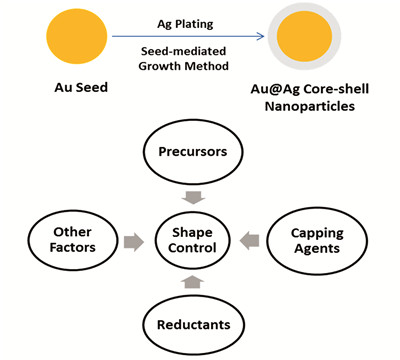

种子生长法制备Au@Ag核壳纳米粒子

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation of Au@Ag Core-Shell Nanoparticles through Seed-Mediated Growth Method

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |