PDF(1764 KB)

PDF(1764 KB)

PDF(1764 KB)

PDF(1764 KB)

PDF(1764 KB)

PDF(1764 KB)

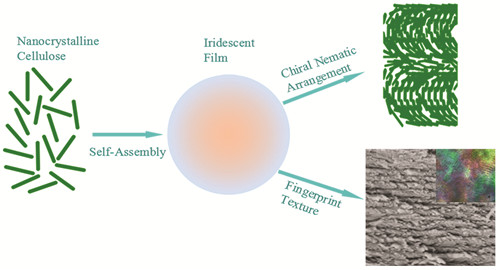

纳米晶纤维素手性向列型液晶相结构的形成、调控及应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Formation, Tuning and Application of Chiral Nematic Liquid Crystal Phase Based on Nanocrystalline Cellulose

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |