PDF(1172 KB)

PDF(1172 KB)

PDF(1172 KB)

PDF(1172 KB)

PDF(1172 KB)

PDF(1172 KB)

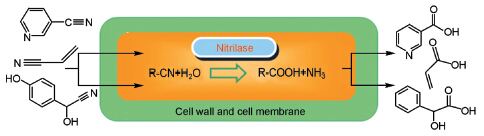

腈水解酶在医药中间体生物催化研究中的最新进展

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Recent Progress in the Application of Nitrilase in the Biocatalytic Synthesis of Pharmaceutical Intermediates

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |