PDF(3038 KB)

PDF(3038 KB)

PDF(3038 KB)

PDF(3038 KB)

PDF(3038 KB)

PDF(3038 KB)

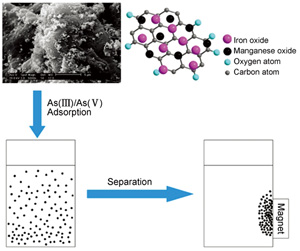

铁锰氧化物/碳基复合材料的制备及其对水中砷的去除

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation of Iron and Manganese Oxides/Carbon Composite Materials for Arsenic Removal from Aqueous Solution

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |