PDF(1735 KB)

PDF(1735 KB)

PDF(1735 KB)

PDF(1735 KB)

PDF(1735 KB)

PDF(1735 KB)

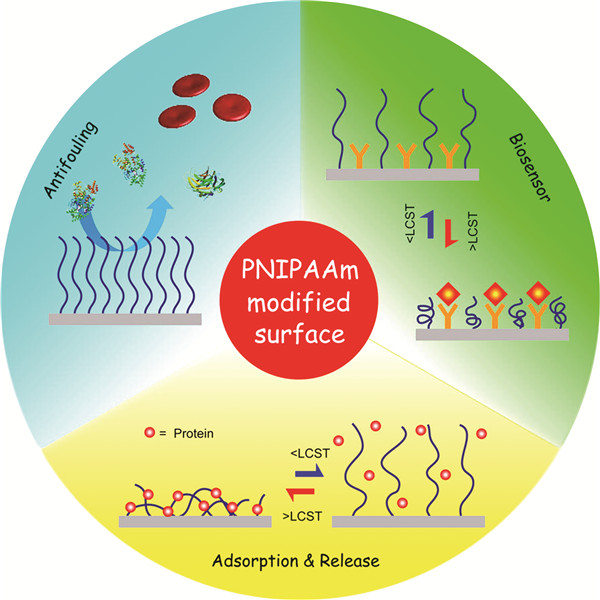

PNIPAAm改性表面对蛋白质吸附的调控及其应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Applications of Regulation of Protein Adsorption Using PNIPAAm Modified Surfaces

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |