PDF(2832 KB)

PDF(2832 KB)

PDF(2832 KB)

PDF(2832 KB)

PDF(2832 KB)

PDF(2832 KB)

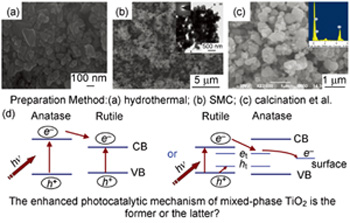

混晶TiO2光催化剂的制备及机理研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Synthesis and Photocatalytic Mechanisms of the Mixed-Phase TiO2 Photocatalysts

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |