PDF(1642 KB)

PDF(1642 KB)

PDF(1642 KB)

PDF(1642 KB)

PDF(1642 KB)

PDF(1642 KB)

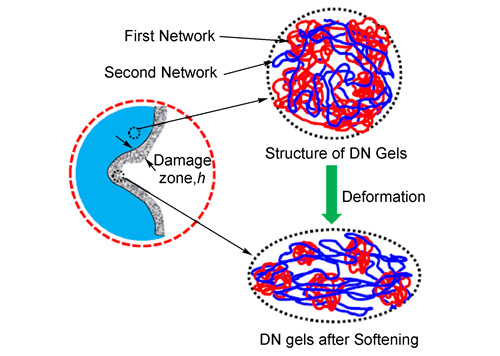

高强度双网络水凝胶的增韧机理

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Toughening Mechanisms of High Strength Double Network Hydrogels

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |