PDF(6186 KB)

PDF(6186 KB)

PDF(6186 KB)

PDF(6186 KB)

PDF(6186 KB)

PDF(6186 KB)

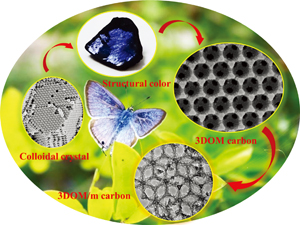

三维有序大孔炭的设计构筑、性能及应用研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Synthesis and Application of Three-Dimensionally Ordered Macroporous Carbon with Designed Pore Architecture

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |