PDF(2320 KB)

PDF(2320 KB)

PDF(2320 KB)

PDF(2320 KB)

PDF(2320 KB)

PDF(2320 KB)

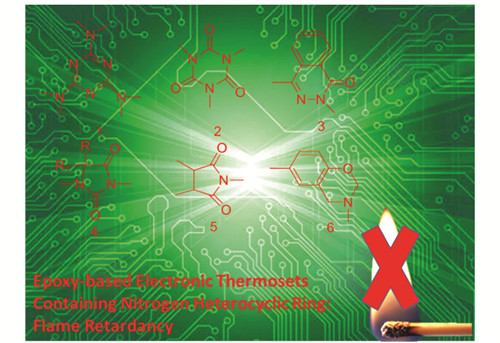

含氮杂环结构的阻燃环氧树脂基电子材料

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Epoxy-Based Electronic Materials Containing Nitrogen Heterocyclic Ring:Flame Retardancy

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |