PDF(4180 KB)

PDF(4180 KB)

PDF(4180 KB)

PDF(4180 KB)

PDF(4180 KB)

PDF(4180 KB)

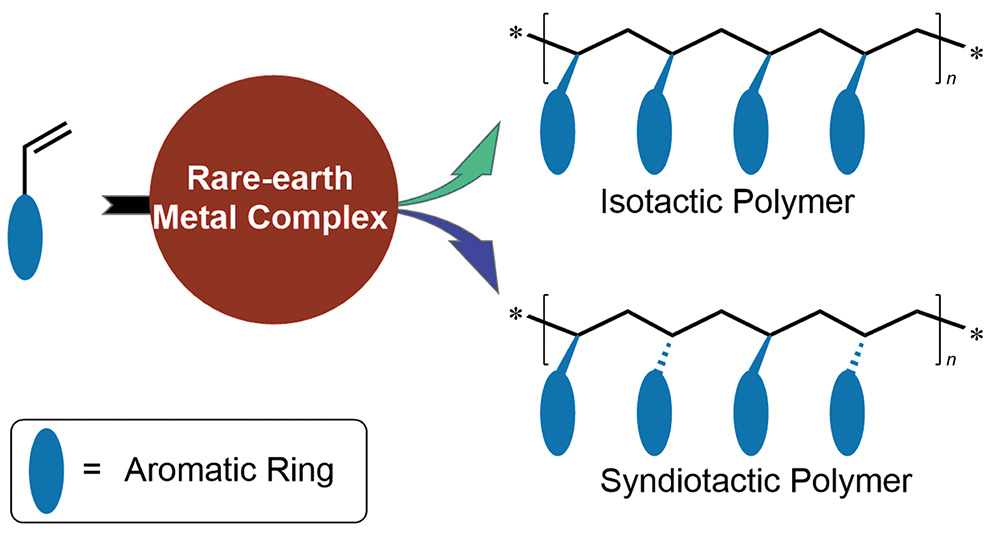

稀土金属配合物催化芳香型乙烯基极性单体立构选择性聚合

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Rare-Earth Metal Complexes-Mediated Stereoselective Polymerization of Aromatic Polar Vinyl Monomers

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |