PDF(9913 KB)

PDF(9913 KB)

PDF(9913 KB)

PDF(9913 KB)

PDF(9913 KB)

PDF(9913 KB)

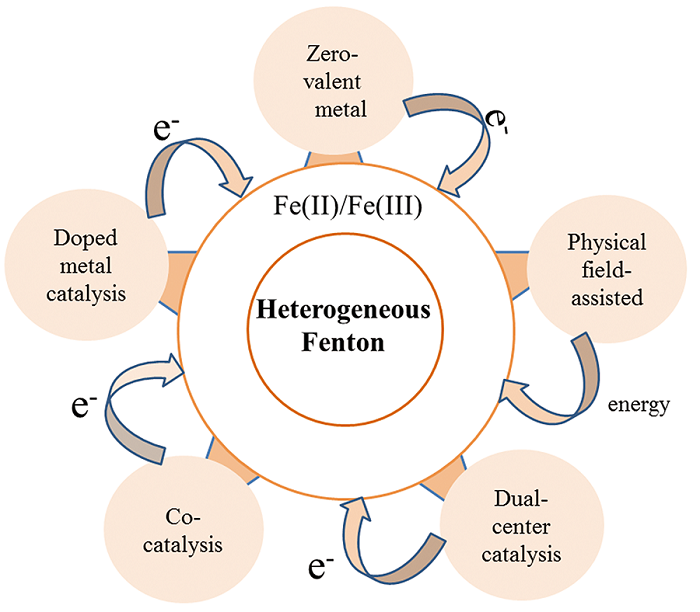

提高非均相芬顿催化活性策略、研究进展及启示

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Strategies, Research Progress and Enlightenment of Enhancing the Heterogeneous Fenton Catalytic Reactivity: A Critical Review

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |