PDF(5861 KB)

PDF(5861 KB)

PDF(5861 KB)

PDF(5861 KB)

PDF(5861 KB)

PDF(5861 KB)

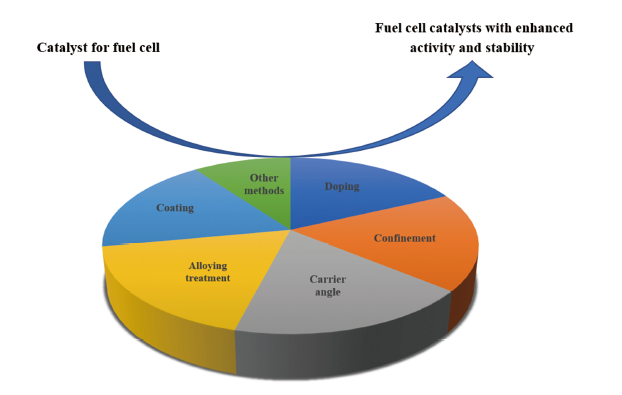

后处理技术提升燃料电池催化剂稳定性

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Post-Treatment Technology Improves Fuel Cell Catalyst Stability

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |