PDF(12819 KB)

PDF(12819 KB)

金属有机骨架材料在氨低温催化还原氮氧化物反应中的应用

王晓晗, 刘彩霞, 宋春风, 马德刚, 李振国, 刘庆岭

化学进展 ›› 2020, Vol. 32 ›› Issue (12) : 1917-1929.

PDF(12819 KB)

PDF(12819 KB)

PDF(12819 KB)

PDF(12819 KB)

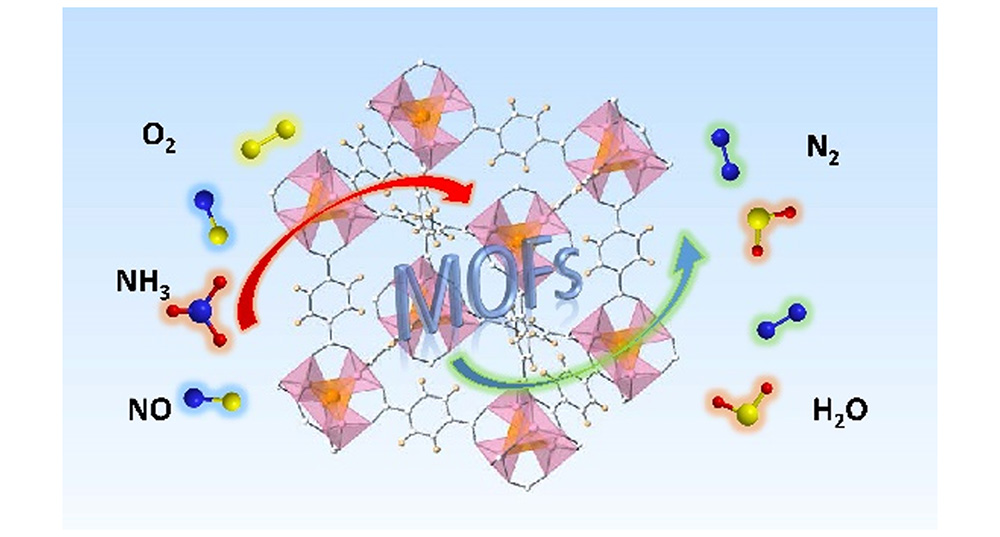

金属有机骨架材料在氨低温催化还原氮氧化物反应中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Application of Metal-Organic Frameworks for Low-Temperature Selective Catalytic Reduction of NO with NH3

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |